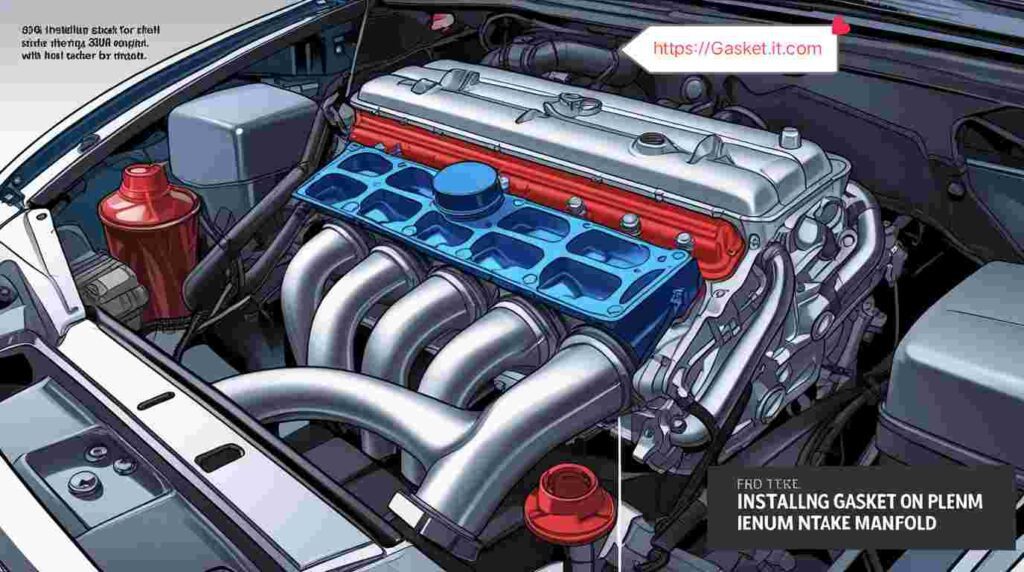

Introduction about 3800 engine plenum intake manifold gasket installation

If you’ve ever owned a car with a General Motors, The 3800 Series engine by General Motors is known for its power, reliability, and long-lasting performance. But like many engines, it can face issues related to the plenum and intake manifold gaskets over time. When these gaskets fail, the engine may leak coolant, misfire, or lose power, affecting both performance and fuel efficiency.

If you’re planning a 3800 engine plenum intake manifold gasket installation, this guide will walk you through every step. Whether you drive a Pontiac Grand Prix, Buick LeSabre, or Chevrolet Impala, this article covers how to replace the gasket, prevent future leaks, and restore your engine’s performance safely.

Understanding the 3800 Engine Intake System

The GM 3800 engine is built with a unique intake system that includes a lower intake manifold (LIM) and an upper plenum. These components control the air and fuel mixture before it enters the cylinders. Over time, the gaskets between them can wear out due to heat cycles and coolant exposure.

When gasket failure happens, coolant leaks into the intake ports or combustion chambers. This causes white smoke, rough idling, or overheating. Early replacement prevents serious engine damage, making gasket installation a vital part of regular maintenance.

Why the Intake Plenum Gasket Fails

If you’ve ever wondered why so many 3800 engines develop coolant leaks over time, the answer often lies in the plenum gasket. The plenum gasket often fails because of thermal stress or degraded plastic material in older designs. The 3800 engine, especially from 1995–2005, is prone to coolant leaks from the EGR port melting the intake surface. Using an updated gasket kit or redesigned plenum helps eliminate this common issue.

Also visit the 3800 Engine Intake System” section

Symptoms Before 3800 Engine Plenum Intake Manifold Gasket Installation

Before doing the repair, it’s important to recognize the signs of a failing gasket. The most common symptom is coolant loss without visible leaks. You may also notice milky oil, engine knocking, or reduced fuel economy.

When these signs appear, a 3800 engine plenum intake manifold gasket installation becomes necessary to prevent long-term damage. Replacing it early can save you from a complete engine rebuild or head gasket replacement.

Read More About: 1956 Buick Special Rear Torque Tube Gasket

Diagnosing a Gasket Leak

You can detect intake gasket failure using a pressure test or by checking for coolant in the throttle body. Removing the upper plenum will often reveal coolant residue near the intake ports. If you find evidence of internal leakage, it’s time to install a new gasket kit immediately.

Tools and Parts You’ll Need for 3800 engine plenum intake manifold gasket installation

Anyone who’s ever worked under the hood knows that preparation can make or break a repair. Every repair is smoother when you’re well-prepared. Before you start, gather all necessary tools and replacement parts. Using OEM-quality components ensures a long-lasting seal and proper fit.

Below is a helpful table showing what you’ll need for a 3800 engine plenum intake manifold gasket installation:

| Tools & Parts Required | Purpose/Description |

| Socket Set & Torque Wrench | Removing and reinstalling bolts accurately |

| Gasket Scraper & Cleaner | Cleaning old gasket material |

| Replacement Gasket Kit | Includes plenum and manifold gaskets |

| RTV Silicone Sealant | Seals corners and critical joints |

| Coolant & Engine Oil | Refill after gasket installation |

| New Upper Intake Plenum (Optional) | Recommended if the old one is damaged |

Recommended Gasket Brands

You can choose brands like Fel-Pro, Mahle, or ACDelco for dependable results. These brands are known for their durability and compatibility with GM 3.8L Series II and III engines.

Step-by-Step 3800 Engine Plenum Intake Manifold Gasket Installation Process

This section explains how to complete the gasket replacement safely. Each paragraph guides you through a phase of disassembly and reassembly.

Start by disconnecting the negative battery terminal and draining the coolant. Then remove the throttle body, fuel rails, and intake plenum carefully. Keep bolts and sensors organized to avoid confusion during reassembly. Cleaning the mating surfaces thoroughly is essential for a leak-free seal.

Now comes the part where everything starts coming back together — the reassembly. Next, install the new lower intake manifold gaskets and apply a small amount of RTV sealant at the joints. Reinstall the plenum with the new gasket kit, tightening all bolts to the recommended torque sequence. Once complete, refill the coolant and start the engine to check for leaks or idle changes.

Post-Installation Checks

After the repair, let the engine run for a few minutes and monitor for coolant leaks. Ensure that the idle stabilizes and there’s no check engine light. Recheck coolant levels after your first test drive to confirm everything is sealed properly.

Common Mistakes During 3800 Engine Plenum Intake Manifold Gasket Installation

Even skilled DIYers can make mistakes during gasket installation. The most common issue is over-torquing bolts, which can cause warping or cracks in the intake plenum. Another mistake is skipping surface cleaning, which leads to poor sealing.

Always follow the torque pattern outlined in your repair manual. Use a torque wrench to achieve accurate results. If the engine overheats after installation, check for trapped air in the coolant system and bleed it correctly.

Expert Tip on 3800 engine plenum intake manifold gasket installation

It might be tempting to cut corners, but that’s where most engine repairs go wrong. Avoid using cheap gasket materials or reused bolts. Investing in high-quality parts and proper tools saves you from repeat repairs and future engine issues.

Preventive Maintenance After Installation

Once your 3800 engine plenum intake manifold gasket installation is complete, follow preventive steps to keep your engine healthy. Regularly check coolant levels, use the correct Dex-Cool or approved coolant type, and perform routine oil changes.

Clean the throttle body and EGR valve periodically to prevent carbon buildup. These small actions significantly extend gasket life and ensure smooth engine performance over time.

When to Recheck the System

After about 500 miles of driving, inspect the intake bolts again. Slight re-torqueing may be required as new gaskets settle. It’s also a good idea to look for any signs of external leaks around the plenum edges.

Cost of 3800 Engine Plenum Intake Manifold Gasket Installation

The average cost of this repair varies depending on labor and parts. If done professionally, expect to spend between $400 and $700. Doing it yourself with a reliable gasket kit can reduce costs to around $100–$150.

If you take pride in keeping your car running like new, this tip’s for you. Whether you’re working on a Pontiac, Buick, or Chevrolet, investing in a proper gasket kit is worth it. The upgraded design prevents coolant leaks and ensures years of smooth driving.

Where to Buy Quality Gaskets

- You can purchase high-quality replacement kits from trusted auto stores or online retailers like RockAuto, Summit Racing, or Amazon. Always verify compatibility with your 3800 Series II or III engine before ordering.

Safety and Environmental Tips for 3800 engine plenum intake manifold gasket installation

During the 3800 engine plenum intake manifold gasket installation, ensure you’re working in a well-ventilated area. Always wear gloves and safety glasses. Avoid spilling coolant into drains—dispose of it safely at recycling centers.

Keep tools organized and use jack stands if you need to lift the car for better access. Taking small safety steps keeps your project smooth and injury-free.

Eco-Friendly Practices

Old gaskets and coolant can harm the environment. Seal used fluids in approved containers and take them to local waste collection points. Responsible disposal protects both you and the environment.

Conclusion about 3800 engine plenum intake manifold gasket installation

At first glance, replacing the plenum and manifold gaskets on your GM 3800 engine may seem tough, but with patience and care, it’s manageable even for beginners. A successful 3800 engine plenum intake manifold gasket installation restores lost performance, prevents coolant leaks, and extends your engine’s life.

Always double-check your torque settings, use OEM-quality gaskets, and inspect your system regularly. Following this complete guide ensures your 3.8L engine keeps running strong for thousands of miles ahead.

FAQs About 3800 Engine Plenum Intake Manifold Gasket Installation

Q1: What are the first signs of a bad intake plenum gasket?

A: Common signs include coolant loss, rough idle, engine misfires, or white exhaust smoke.

Q2: Can I drive with a leaking plenum gasket?

A: It’s not recommended. Driving with a leak can cause severe engine damage or coolant contamination in the oil.

Q3: How long does the installation take?

A: Typically, it takes about 4–6 hours for experienced DIYers and 2–3 hours for professionals.

Q4: Do I need to replace the upper intake plenum too?

A: If the plenum shows heat damage or cracking near the EGR port, replacement is strongly advised.

Q5: What torque specs should I use for the intake bolts?

A: Follow your vehicle’s repair manual; typically, the range is 11–18 ft-lbs depending on bolt location.

Q6: Can a bad gasket cause coolant to mix with oil?

A: Yes, when the gasket fails, coolant can leak into the oil passages, creating a milky residue.

Q7: What coolant is best after installation?

A: Use GM-approved Dex-Cool or compatible long-life coolant for best performance.

Q8: Is gasket sealant required during installation?

A: Apply RTV sealant only at the corner joints or as specified by the kit instructions.

Q9: How often should I replace the intake gaskets?

A: Generally every 100,000 miles or sooner if leaks or overheating occur.

Q10: Can this repair improve fuel efficiency?

A: Yes, proper sealing restores combustion efficiency and improves overall fuel economy.