Diesel truck owners often face serious engine issues, and few are as stressful as head gasket failure. The 6.4 powerstroke head gasket problem has become well known due to high heat, boost pressure, and factory design limits. When sealing fails, coolant loss, white smoke, and overheating quickly follow. Understanding why this issue happens is the first step toward protecting your engine and avoiding sudden, costly breakdowns.

This article explains real causes, warning signs, repair options, and prevention strategies. You will learn about costs, replacement methods, and proven upgrades that improve reliability. Written in simple language, it helps both new and experienced owners make smart decisions, save money, and extend the life of their diesel truck with confidence and long-term durability.

Why the 6.4 Powerstroke Head Gasket Fails More Often Than Expected

Understanding the real pressure behind failures

The 6.4 powerstroke head gasket is one of the most discussed topics among diesel truck owners. Many drivers face sudden coolant loss, white smoke, or overheating. These problems often start small but grow fast. This engine runs hot by design, and high boost pressure adds stress. Over time, factory gaskets struggle to keep a perfect seal.

Another reason is torque stretch. Stock head bolts can loosen under extreme load. When combustion pressure escapes, it damages the gasket layers. This is why owners see repeat failures. Understanding this issue early helps avoid expensive engine damage. A strong gasket solution paired with better hardware makes a big difference.

Common Warning Signs of a 6.4 Powerstroke Head Gasket Failure

Symptoms you should never ignore

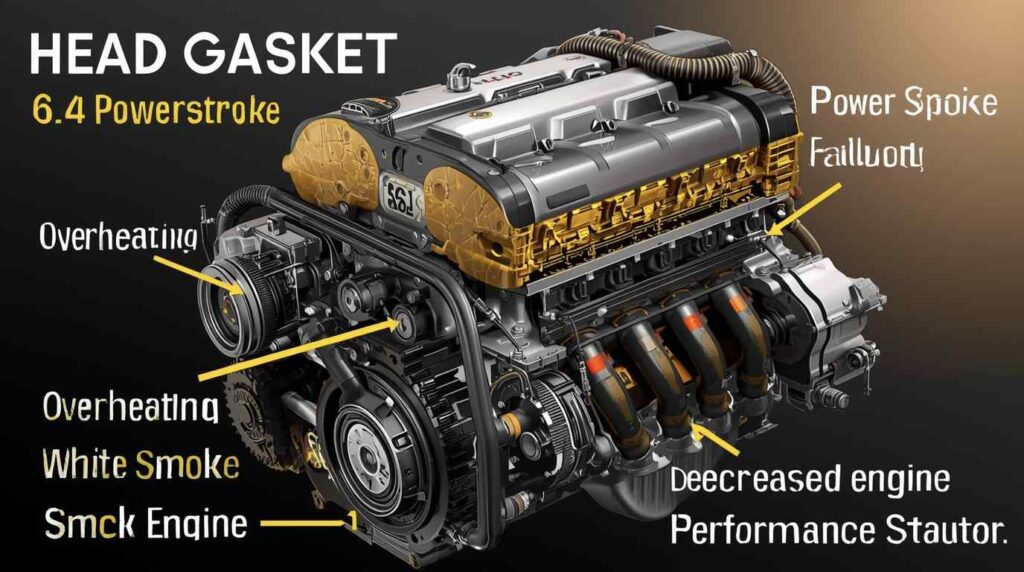

A failing 6.4 powerstroke head gasket shows clear signs if you pay attention. Coolant pushing out of the reservoir is a major red flag. You may also notice bubbling in the degas bottle. This happens when exhaust gases enter the cooling system.

White smoke from the exhaust is another signal. It usually means coolant is burning inside the cylinders. Some drivers also experience hard starts and rough idling. These symptoms match many 6.4 powerstroke blown head gasket symptoms reported by owners. Catching these signs early can save thousands in repairs.

What Causes Repeated 6.4 Powerstroke Head Gasket Problems

Design limits and driving habits

The 6.4 powerstroke head gasket problem is not always about poor maintenance. The engine produces high cylinder pressure. Aggressive tuning makes it worse. Heavy towing without proper cooling also increases risk. Heat cycles slowly weaken gasket material.

Another cause is uneven clamping force. Factory bolts stretch over time. Once they lose tension, sealing pressure drops. This leads to combustion leaks. Many mechanics now recommend upgrading hardware during repairs. Solving the root cause prevents future breakdowns and improves long-term reliability.

Choosing the Right 6.4 Powerstroke Head Gasket Kit

OEM vs aftermarket explained simply

Selecting a 6.4 powerstroke head gasket kit depends on your goals. OEM kits are good for stock trucks. They match factory specs and fit perfectly. However, they may fail again under heavy use.

Aftermarket kits often include multi-layer steel gaskets. These handle heat better. Some kits also pair well with studs. A 6.4 powerstroke head gasket and stud kit offers stronger clamping force. This combo is popular with owners who tow heavy or run mild tunes.

Is the 2008 6.4 Powerstroke Head Gasket Different

Year-specific considerations

The 2008 6.4 powerstroke head gasket design is similar to later models. However, early engines sometimes show faster wear. Cooling system updates improved later reliability. Owners of 2008 models should inspect cooling components closely.

Many shops recommend a 2008 6.4 powerstroke head gasket kit that includes updated seals. This ensures compatibility and better durability. Matching the correct kit to your model year avoids fitment issues and reduces installation time.

Understanding 6.4 Powerstroke Head Gasket Replacement Cost

What you really pay for

The 6.4 powerstroke head gasket replacement cost can surprise many owners. Parts alone are not the biggest expense. Labor takes most of the budget. The cab often needs to be lifted for proper access.

Costs vary by region and shop skill. On average, repairs range from several thousand dollars. Adding studs increases cost upfront but saves money later. A proper repair prevents repeat failures and protects your engine investment.

Step-by-Step Overview of 6.4 Powerstroke Head Gasket Replacement

What happens during the repair

A professional 6.4 powerstroke head gasket replacement starts with engine teardown. Technicians inspect heads for warping. Machining may be required for a perfect seal. Old gaskets are removed carefully.

New gaskets are installed with precise torque specs. Many shops upgrade to studs at this stage. Fluids are replaced, and systems are pressure tested. A careful process ensures reliability and long service life.

Preventing Future 6.4 Powerstroke Head Gasket Failures

Smart upgrades and habits

Protecting your 6.4 powerstroke head gasket starts with cooling. Upgraded radiators and coolant filters help control heat. Monitoring gauges prevents surprises. Avoid aggressive tuning without proper support mods.

Using quality fuel and oil also matters. Regular maintenance reduces stress on engine components. Many owners who follow these steps report fewer issues and longer engine life.

Real-World Experience With Blown 6.4 Powerstroke Head Gaskets

Lessons from owners and mechanics

Drivers who experienced a 6.4 powerstroke blown head gasket often share similar stories. Small symptoms were ignored. A minor coolant issue became a major repair. Those who upgraded components early avoided repeat failures.

Mechanics agree that prevention is cheaper than repair. Strong gaskets, better hardware, and smart driving habits make the engine far more reliable. Experience proves that the right fix works.

Is Fixing the 6.4 Powerstroke Head Gasket Worth It

Final verdict for owners

Repairing a 6.4 powerstroke head gasket is absolutely worth it when the job is done the right way. Many owners fail not because of the engine, but because of shortcuts. Cheap parts or rushed labor almost always lead to repeat failures. A complete and well-planned repair brings back lost power, smooth performance, and peace of mind.

When quality gaskets, proper hardware, and skilled hands come together, this engine proves its strength. Countless trucks on the road today are living proof. Owners who invest wisely enjoy confident towing, reliable daily driving, and fewer shop visits. Fix it once, fix it right, and the 6.4 Powerstroke can reward you with years of dependable performance.

Conclusion

The 6.4 powerstroke head gasket may be a well-known weak point, but it does not mean the engine is doomed. Many owners panic when symptoms appear, yet the truth is simple. Knowledge changes everything. When you understand the warning signs, root causes, and correct repair methods, you regain control.

A proper fix using quality parts, combined with smart upgrades like improved cooling and stronger hardware, transforms reliability. The key is acting early and fixing the problem the right way. Thousands of trucks are still running strong today because their owners chose informed repairs over shortcuts. Address it correctly once, and this engine can deliver years of dependable performance instead of repeated trips to the repair shop.

FAQs

What causes head gasket failure in the 6.4 Powerstroke engine

High engine heat and extreme cylinder pressure are the main causes. The factory design runs hot, especially under towing or tuning. Over time, this stress weakens the gasket seal and allows combustion gases to escape.

What are the most common symptoms of a blown head gasket

Drivers usually notice coolant loss, pressure in the degas bottle, white exhaust smoke, and overheating. Hard starts and rough idle can also appear as the problem worsens.

Can I continue driving with a blown head gasket

Driving is risky even for short distances. Coolant can enter cylinders and damage pistons or bearings. Continuing to drive often turns a repair into a full engine rebuild.

Is replacing the head gasket a permanent fix

It can be permanent if done correctly. Using quality gaskets, proper machining, and stronger fasteners greatly improves long-term reliability and prevents repeat failures.

Are head studs better than factory head bolts

Yes, studs provide stronger and more consistent clamping force. They do not stretch like factory bolts, which helps the gasket maintain a tight seal under high pressure.

How long does head gasket replacement usually take

Most professional shops take several days. The cab is often removed to access the engine properly. Rushing the job increases the chance of future problems.

Does engine tuning increase head gasket failure risk

Aggressive tuning raises boost and cylinder pressure. Without cooling upgrades and stronger hardware, tuning significantly increases the risk of gasket failure.

What is the average repair cost

Costs vary by location and parts used. Labor is the biggest expense due to engine access. Adding studs costs more upfront but saves money long term.

Can overheating alone damage the head gasket

Yes, repeated overheating weakens gasket layers and warps cylinder heads. Even one severe overheat event can start gasket failure.

How can I prevent future head gasket issues

Monitor engine temperature, maintain the cooling system, avoid extreme tuning, and use quality parts. Preventive care is far cheaper than major repairs.