The demand for controlled finishing environments is rising across industrial and automotive sectors, and industrial paint booths manufacturers uzbekistan are becoming increasingly relevant in this space. Businesses involved in vehicle refinishing, metal fabrication, and large equipment coating rely heavily on structured spraying environments to achieve uniform finishes and controlled airflow. These systems are designed to manage overspray, improve surface quality, and maintain safe working conditions. As industries expand and production expectations increase, proper booth selection becomes a practical necessity rather than a luxury.

Manufacturers and suppliers in this category focus on delivering booths that serve varied production needs, from small components to full-sized commercial vehicles. The growing awareness around workspace safety, air quality, and process efficiency has made these enclosures standard equipment rather than optional tools. Understanding how different booth types work, what features they offer, and where they are used helps businesses make informed purchasing decisions based only on performance and suitability.

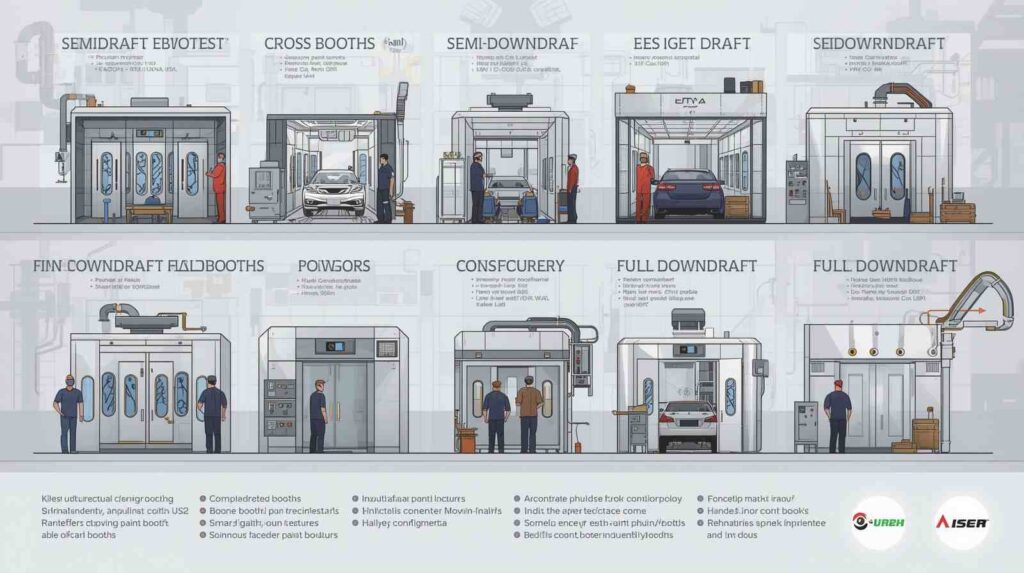

Types and Configurations of Paint/Spray Booths – industrial paint booths manufacturers uzbekistan

Paint booth designs are structured to match specific airflow patterns, workspace sizes, and production demands. industrial paint booths uzbekistan manufacturers supply different configurations that suit both compact workshops and large-scale industrial plants. Each configuration is engineered to control air movement, capture overspray, and support consistent coating application. Selection depends on work volume, vehicle size, and the level of finish quality required in daily operations.

One smart layout choice can completely change how smoothly an entire workshop runs. Different layouts also allow flexibility for varying shop dimensions and workflow setups. Some booths support drive-through operations for larger vehicles, while others are built for stationary refinishing of smaller components. Choosing the right type directly influences material efficiency, operator comfort, and final surface results. A proper match between booth configuration and intended application ensures smoother production and better long-term equipment performance.

Explore Paint Spray Booth

Cross-draft / Open-Face Booths – industrial paint booths manufacturers uzbekistan

Cross-draft and open-face booths are among the simplest and most direct designs available. Air enters from the front opening and moves horizontally toward the exhaust filters at the rear of the booth. This design allows vehicles or parts to be positioned easily without complicated pit systems. industrial paint booths manufacturers uzbekistan include these models for operations that need basic airflow control without heavy structural modifications.

These booths are typically used in facilities where space is limited and rapid job turnover is important. While they may not provide the most advanced air control, they offer reliable overspray management and accessible operation. Their straightforward structure makes them popular in repair shops and general refinishing areas where flexibility matters more than ultra-precision airflow control.

Downdraft Booths (Pit / Side / Modified) – industrial paint booths manufacturers uzbekistan

Downdraft booths utilize vertical airflow that moves from the ceiling directly down toward floor-level filters or pits. This airflow pattern pulls overspray away from the painted surface quickly and reduces the chance of contaminants settling on fresh coatings. Many industrial paint booths manufacturers uzbekistan offer downdraft systems in full-pit, side-pit, and modified configurations to suit different facility layouts.

When absolute surface perfection is non-negotiable, the downdraft setup instantly becomes the top choice. The downdraft setup is widely known for its ability to deliver high-quality finishes with minimal surface defects. By maintaining even airflow across the entire work area, this booth design supports consistent curing and cleaner paint results. It is commonly used in high-precision refinishing and industrial coating environments where surface perfection is a production priority.

Booths for Large Vehicles: Truck / Bus / Industrial Equipment – industrial paint booths manufacturers uzbekistan

Large vehicle booths are specifically built to handle oversized applications such as buses, trucks, and industrial machinery. These booths feature extended lengths, reinforced structures, and high-capacity airflow systems to support heavy-duty coating operations. industrial paint booths manufacturers uzbekistan design these enclosures to allow safe entry and exit of bulky vehicles while maintaining controlled air movement.

These larger configurations often include drive-through capabilities and multiple access doors for efficient workflow. Their internal space allows technicians to move freely around the vehicle without airflow disruption. Such booths are essential for industries that handle fleet maintenance, commercial transport equipment, and large-scale industrial production units.

Key Features & Construction Details of Spray Booths – industrial paint booths manufacturers uzbekistan

The structural design of a spray booth determines its durability, performance, and operational safety. Materials used in frame construction, wall panels, and access doors must withstand continuous exposure to chemicals and airflow pressure. industrial paint booth manufacturer uzbekistan systems emphasize closed-panel designs that minimize air leakage and maintain stable internal pressure during operation.

At the heart of every high-performing paint booth is one simple truth: airflow decides everything. Beyond structural stability, airflow management and filtration form the operational core of a booth system. Proper ventilation ensures that fresh air enters the booth consistently while contaminated air exits efficiently. Filtration units are positioned strategically to capture overspray particles and protect both workers and surrounding equipment from harmful exposure.

Read More About: Evaluate the computer manufacturing company kontron on industrial pcs

Structural Materials and Build Quality – industrial paint booths manufacturers uzbekistan

Spray booth panels are commonly made from insulated metal sections that offer both thermal control and structural strength. These materials provide resistance against corrosion and allow booths to retain temperature stability during painting and curing cycles. industrial paint booths manufacturers uzbekistan rely on modular panel construction to allow easier installation and future expansion.

The quality of hinges, doors, and sealing systems also contributes to booth performance. Tight seals prevent air leaks that could disrupt airflow balance. A solidly constructed booth maintains consistent pressure and airflow speed, which directly affects coating quality and operational efficiency across repeated production cycles.

Airflow, Ventilation & Filtration Systems – industrial paint booths manufacturers uzbekistan

Ventilation systems regulate how air enters and exits the booth and determine how effectively overspray is removed. Intake plenums introduce clean air, while exhaust systems pull contaminated air through filtration stages before release. industrial paint booths manufacturers uzbekistan integrate multi-stage filters that capture both heavy particles and finer airborne contaminants.

Balanced airflow helps prevent dust accumulation and uneven paint distribution. When air velocity is maintained evenly across the working zone, painted surfaces dry more uniformly. This consistency improves surface appearance and reduces the need for costly rework or touch-ups after curing.

Flexibility, Custom Sizing and Layout Options – industrial paint booths manufacturers uzbekistan

No two workshops are ever built the same—and modular design finally solves that challenge. Modular booth construction allows manufacturers to create enclosures that fit specific facility dimensions. Custom sizing supports narrow workshops as well as expansive industrial production floors. industrial paint booths manufacturers uzbekistan often provide adjustable wall lengths, door placements, and ceiling heights to match workflow demands.

Flexible layout configurations also support process optimization. Some booths are designed for straight-through vehicle movement, while others are optimized for stationary spraying. This adaptability allows businesses to align their coating operations with existing congestion patterns and equipment placement without overhauling the entire facility.

Uses and Suitable Applications for Spray Booths – industrial paint booths manufacturers uzbekistan

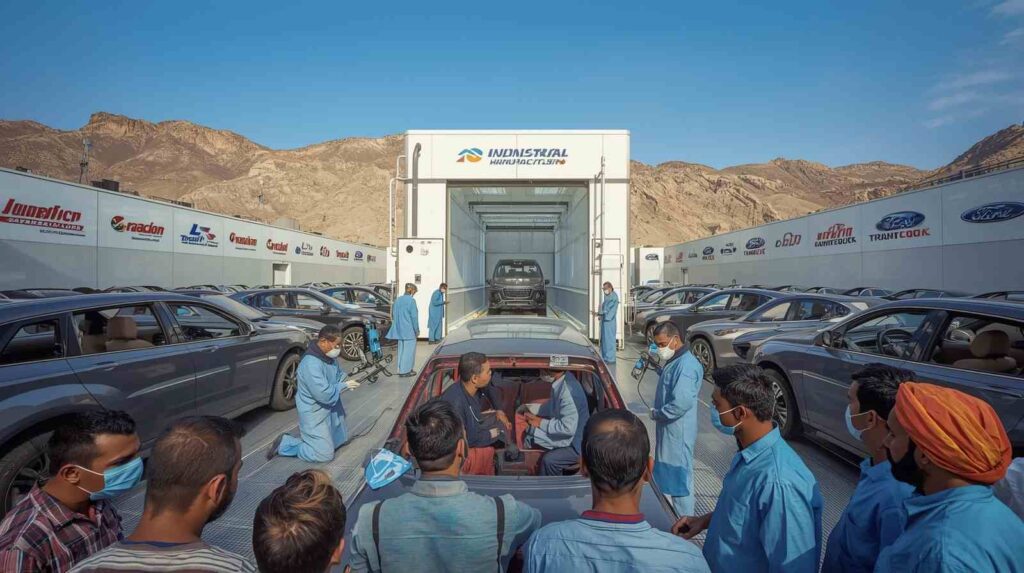

Spray booths serve a wide range of industries where surface finishing quality, safety, and environmental control are required. industrial paint booths manufacturer uzbekistan solutions are used wherever controlled coating conditions improve appearance and product durability. From collision repair centers to specialized equipment manufacturing plants, these systems form the backbone of modern finishing operations.

Different industries demand different booth configurations based on material type, production volume, and quality expectations. While the fundamental purpose remains overspray control and airflow management, the actual usage varies greatly depending on the type of product being coated and the operating environment.

Automotive Repair, Collision & Refinishing Shops – industrial paint booths manufacturers uzbekistan

Automotive refinishing operations depend heavily on stable airflow and dust control. A clean environment ensures that repaired panels blend perfectly with surrounding bodywork. industrial paint booths manufacturers uzbekistan support these facilities with booths designed for quick turnover and consistent finishing.

Collision centers rely on these systems not only for quality results but also for compliance with workplace safety requirements. By capturing harmful vapors and controlling airflow, spray booths allow technicians to work efficiently while maintaining regulated environmental conditions throughout daily production.

Industrial, Aerospace, Bus/Truck, Furniture, and Specialty Manufacturing – industrial paint booths manufacturers uzbekistan

Beyond automotive use, spray booths serve a wide spectrum of industrial manufacturing processes. Heavy equipment parts, structural components, furniture pieces, and aerospace components all require controlled finishing conditions. industrial paint booths manufacturers uzbekistan supply large-format booths where multiple components can be coated in a single cycle.

These industries benefit from consistent coating thickness, reduced material waste, and improved surface durability. The ability to apply finishes evenly across large or complex parts improves overall product performance while supporting long-term operational efficiency in manufacturing environments.

What to Consider When Choosing a Paint Booth – industrial paint booths manufacturers uzbekistan

Selecting the right paint booth involves evaluating application requirements, facility constraints, and desired production outcomes. industrial paint booths manufacturer uzbekistan offerings vary widely in size, airflow design, and structural layout, making it important to match equipment capabilities with operational needs. Each decision influences productivity, finish quality, and long-term maintenance demands.

Facility layout also plays a critical role in booth selection. Ceiling height, floor load capacity, and vehicle movement paths must align with the booth’s physical dimensions. A properly matched booth reduces workflow disruptions and ensures that coating operations integrate smoothly with surrounding production systems.

Type vs Application — matching booth design to work (cars, trucks, parts) – industrial paint booths manufacturers uzbekistan

Different booth designs support different coating needs. Small-part booths focus on compact airflow patterns, while full-vehicle booths support complete automotive refinishing. industrial paint booths manufacturers uzbekistan offer both categories to address diverse production scales.

Matching the booth type to the intended application ensures that airflow reaches all coated surfaces evenly. Inadequate booth sizing can cause turbulence, uneven drying, and inconsistent coating thickness. A properly aligned design improves productivity and ensures predictable finish quality across all work cycles.

Airflow & Finish Quality — how design impacts paint results – industrial paint booths manufacturers uzbekistan

Airflow direction, speed, and balance determine how paint particles settle on surfaces. Vertical airflow offers better overspray control, while horizontal airflow emphasizes accessibility. industrial paint booths manufacturers uzbekistan design booths to maintain steady air velocity that supports even coating and efficient curing.

When airflow is optimized, paint dries uniformly without streaking or contamination. This directly improves surface appearance and reduces post-process correction work. Consistent airflow is essential for achieving stable finish quality in continuous production environments.

Safety, Compliance & Installation Requirements – industrial paint booths manufacturers uzbekistan

Installation considerations include electrical systems, ventilation duct routing, and flooring preparation. Booths must comply with workplace safety regulations related to airflow control and vapor management. industrial paint booths manufacturers uzbekistan develop systems that integrate safely into industrial facilities without compromising surrounding operations.

Proper installation protects both workers and equipment by ensuring controlled air movement at all times. Compliance with safety standards helps facilities avoid costly downtime, health risks, and regulatory complications that could interrupt workflow.

Conclusion

The growing reliance on controlled coating environments clearly shows why industrial paint booths manufacturers uzbekistan continue to hold strong relevance across automotive and industrial sectors. From small refinishing workshops to large-scale manufacturing units, paint booths provide the airflow control, surface protection, and operational consistency required for reliable finishing results. Different booth configurations, construction quality, airflow systems, and application-specific designs all work together to support production goals while maintaining safe working conditions. When matched correctly to the task, these systems help reduce material waste, improve finish quality, and sustain long-term operational efficiency.

Choosing the right booth arrangement ultimately depends on understanding how booth types, airflow direction, structural design, and installation requirements align with actual production needs. Whether the focus is automotive refinishing, large vehicle coating, or industrial manufacturing, the right booth ensures smoother workflow, better surface outcomes, and greater workplace control. By carefully evaluating application demands and facility layout, businesses can select solutions that support reliable performance and consistent results across every project.

FAQs

1. What is the main purpose of an industrial paint booth?

An industrial paint booth is designed to create a controlled environment for coating applications. It manages airflow, captures overspray, and prevents dust or contaminants from settling on painted surfaces. This results in better finish quality, safer working conditions, and improved material efficiency during painting and curing processes.

2. How do different paint booth configurations affect performance?

Paint booth configurations such as cross-draft, downdraft, and large-vehicle booths influence airflow direction and contamination control. Cross-draft booths offer simple, front-to-back airflow, while downdraft systems pull air vertically for cleaner finishes. Large-vehicle booths are built to handle trucks, buses, and heavy equipment with stable airflow across wide spaces.

3. Why is airflow balance important inside a spray booth?

Balanced airflow ensures even paint distribution and proper drying. If airflow is uneven, it can cause paint defects, contamination, or inconsistent coating thickness. Proper ventilation keeps operators safe while maintaining surface quality and production efficiency.

4. What industries commonly rely on industrial paint booths?

Industrial paint booths are widely used in automotive repair, collision centers, bus and truck refinishing, furniture manufacturing, aerospace components, and general industrial production where controlled coating is required.

5. What should be considered before installing a paint booth?

Key factors include booth size, workspace layout, airflow design, safety compliance, electrical requirements, and installation space. Proper planning ensures smooth workflow, regulatory compliance, and long-term operational reliability.

Thanks you for visit Gasket.it.com